Cristalería Reina: Innovation and Tradition in Glass Processing

Exploring the Evolution of a Family Business, its Strategic Partnership with TUROMAS and the Impact of Technology on its Sustained Success.

The Reina glassworks is a family business that stands out for its trajectory. The company was founded in 1958 in Villamartin, Ildefonso Reina Coca took the first steps as a wood carpentry, but over time they became a benchmark in the glass sector, thanks to their dedication and vision. Since then, the evolution has been constant.

Cristalería Reina. Montellano, Sevilla

The choice of TUROMAS machines not only responds to criteria of efficiency and quality, but also reflects a special and lasting relationship based on mutual trust and commitment to excellence.

We were able to talk to Ildefonso Reina, son of the founder. Through the words of his representative, we will explore the challenges, opportunities and vision for the future of this leading company in the glass sector, as well as its partnership with TUROMAS and the impact of technology on its production process.

What is EMPRESA? Explanation of the COMPANY (history, structure, vision and values of the company, presence in the world, core business, company philosophy, processes, customers, etc.).

Our history began in Villamartin in 1958, when Ildefonso Reina Coca founded the family business with a wood carpentry shop that was maintained until 1975, when it was decided to undertake the first expansion of the company to add glass to its business offer. This new stage lasted until 1991, when Cristalería Reina was founded, with Ildefonso Reina Perea at the head of the company.

A year later, due to the strong growth of the business in these years, the construction of new facilities of 2.000 m2 in the Pol. Ind. El Chaparral in Villamartín, and in 2003 these facilities were extended again, adding a further 1,000 m2 to meet the needs of the business.

In 2004 we decided to focus exclusively on the glass business, specialising more and more, generating and building up our client portfolio, which led to the constant growth of the business and once again, as a result of enthusiasm, effort and a job well done, in 2008, after acquiring 80,000 m2 of land in Montellano to guarantee the continuity, growth and updating of the company for the next generations, work began on the new plant to meet the demands of the 21st century.

Thus, in 2009, production began at the 15,000 m2 Montellano facilities, which are equipped with state-of-the-art technology and machinery that allows us to meet the present and future requirements of the market and our customers.

How did the need for the new TUROMAS cutting machines arise?

Due to the growth of the company we needed to improve the process and expand the glass cutting capacity with two fundamental premises, efficiency in the process and quality in the cut.

What models of TUROMAS machines have been installed? Why are these machines the best for COMPANY? What would you highlight about them?

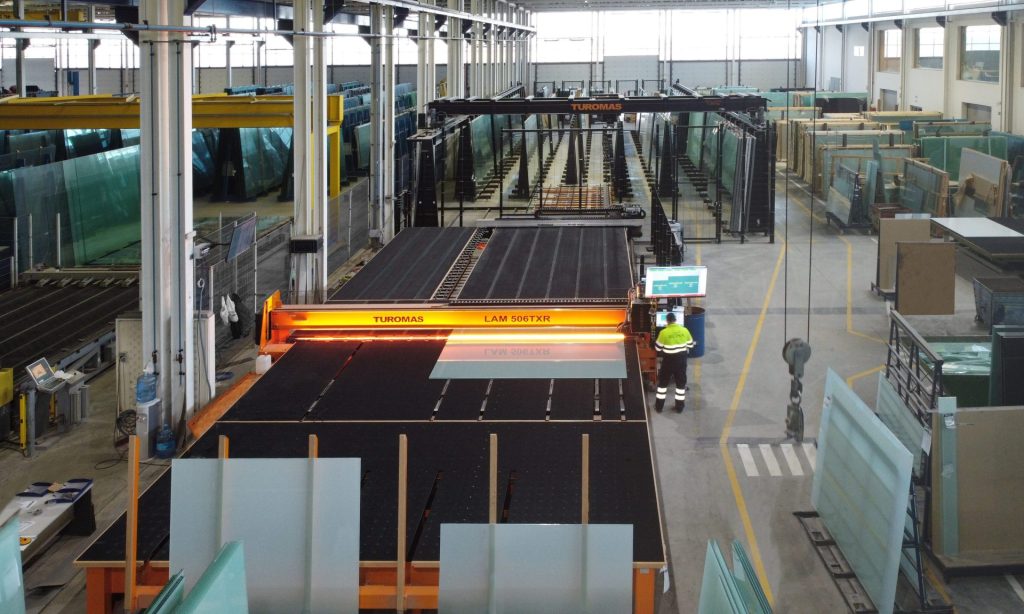

Automatic overhead loader LA-06-RO + Automatic mixed cutting line for laminated and monolithic glass LAM 506TXR.

From our beginnings we have always had a “special” relationship with Turomas and this has weighed heavily in our decision, despite having offers from other manufacturers, in our DNA is that companies are made by people and the Turomas team have always adapted very well to our needs, with full support and backing with a treatment and exceptional after-sales service and that for us is very important so we had no doubt that the offer of TUROMAS for us was the most attractive proposal.

We are convinced that it is a winning bet, the combination of reliability and technology guarantee that we can meet the quality and productivity requirements demanded by the market.