Live glass, live TUROMAS. Return of TUROMAS to Glasstec.

#TuromasInTheWorld

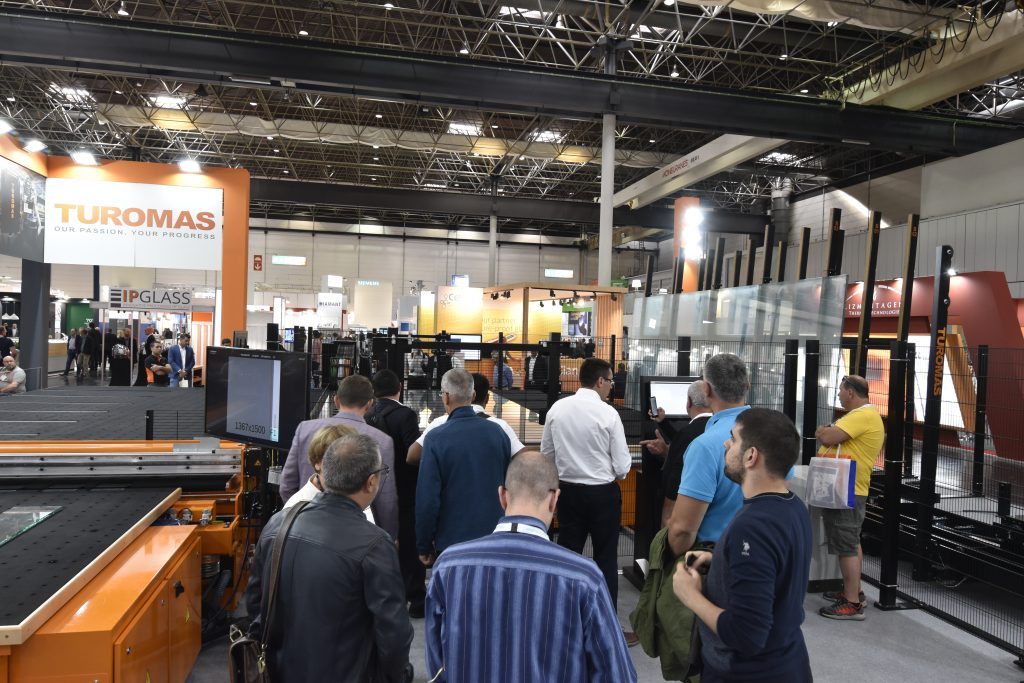

This year Glasstec returned under the slogan Let's go live, and ended with record figures that supported it being held by the glass sector. Turomas, the Spanish manufacturer of machinery for storing, loading and cutting glass, participated as an exhibitor after 4 years of waiting.

During the 4 days of the trade fair, from 20-23 September, more than 30,000 visitors from over 120 countries came to Düsseldorf to be convinced of the innovative power of this industry.

In keeping with the motto of the fair, TUROMAS wanted everyone who visited the stand to be able to “experience glass” and “experience the TUROMAS product”. So, during the 4 days of the fair, it opened its stand, its rooms and machines so that visitors could enjoy first-hand the latest developments that demonstrate new and exciting opportunities for the Spanish company.

Expectation in the machinery area

Sales staff and customers chatting in the bar area.

In this edition, TUROMAS was represented by Miguel Tomás, its President; Antonio Ortega, General Manager; Álvaro Tomas, Vice President; Álvaro Doñate, Commercial Director for Spain and Portugal, Oriol Llorens, Commercial Director for Europe; Rodrigo Duarte, Brazilian Market Representative; Juan Dávila, Commercial Delegate in Colombia; Eduardo Nieto, Commercial Delegate in Chile; and Teresa Catalán, Marketing Manager.

This year, the R&D team also joined the fair: Miguel Ángel Guillén, Team Manager, with Javier Silva, Ángel Silva and José Solsona.

TUROMAS would also like to thank its sales and distribution network, who were also present at the stand throughout the fair and made the team even stronger; offering greater and more personalised customer service.

The TUROMAS team at the stand

In the first picture Antonio Ortega, Director General and Álvaro Tomas, Vice President.

In the second picture Juan Dávila, Eduardo Nieto and Rodolfo Figueredo, commercial delegates for Latin America.

The business team was satisfied with the attendance and reception at the fair. The participation of TUROMAS was very gratifying; as was publicising the advances, innovations and trends, while strengthening commercial relationships.

The image of a reliable, high quality company, which had been in place for many years, was consolidated. This was reflected in the number of former customers who came to say hello and the large number of potential customers interested in fully automated solutions.

Most of the visitors TUROMAS received were from Europe, although there were also representatives from Morocco, Tunisia, Libya, Egypt, South Africa, Saudi Arabia and the United Arab Emirates, among others.

The R+D department commenting on innovations in TUROMAS SOFTWARE.

Statements

The customer profile at the show has continued to evolve towards higher volume processors requiring a higher degree of automation.

Turomas has therefore established itself not only as a machinery manufacturer, but also as a benchmark in engineering solutions and integrated automation projects.

In addition, customers who visited our stand have shown loyalty and appreciation for the brand, with a special mention made of the after-sales service received.

Several projects were closed in Argentina, Mexico, Cyprus and South Africa as well as the largest project in our history in Ireland. There was also a large presence from our Latin American customers, especially Mexico with a large number of companies and projects. In addition, the main Australian companies attended our stand, thanks to collaboration with our official distributor Innovync. We also had very important meetings with some of the main companies in India, United Arab Emirates, Saudi Arabia and Egypt. The fair was undoubtedly the best in our history in terms of results and the quality of visits.

It is worth noting the large number of visits we had from national customers and Portugal and the projects that are active, many of which should materialise in the coming weeks and in the medium term. The number of Canary Islands and Portuguese customers was significant. We would like to thank the national sales network for attending to the rest of our customers throughout.

All of them conveyed a sense of accessibility and satisfaction to us (as well, of course, as the rest of the "export" customers): the result of work carried out during almost 40 years of the company's history.

The most important fair for Turomas, at a good time, with challenges to materialise, reaping the rewards of everyone's work and effort and, at the same time, a bit of "fresh air" to face the uncertainty that is stalking us.

Companies in countries where we were not present until recently are now familiar with TUROMAS as a company with reliable and high quality machines.

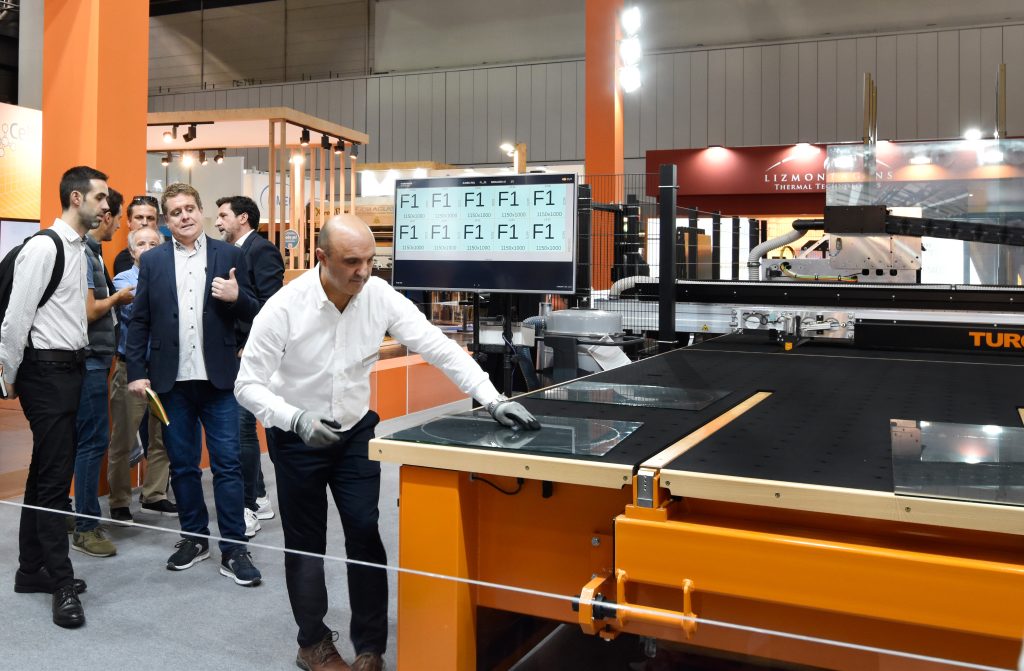

For example, there were live demonstrations of 8+8 glass cutting with our compact laminated cutting machine, which has a cutting time of less than 50 seconds in 8+8 and exceptional cutting quality. This was noticed by many of the small glass processors who thanked us for bringing a machine for this large group of glassmakers to the fair.

Special mention must also be made of the shuttle + loading and cutting table solution for jumbo glass, whose reduced space and performance offered in terms of time were overwhelming.

The software shown at the show, together with the live EasyPro glass stripping demonstrations, were the icing on the cake; delighting every glass processor who knows the current limits on the market and seeing how Turomas has far exceeded them.

In short, the constant presence at our stand of customers and new people from all over the world, interested in becoming part of the great Turomas family, made it a fair in which the company showed an image of growth and great success.

Left, Javier Silva talking to customers about TUROMAS machines. Right, José Solsona showing a cutting simulation.

At Glasstec, TUROMAS presented the main technologies for smart storage, loading and automatic glass cutting, as well as the new software suite. These were live demonstrations, personalised for each customer, creating a unique, intimate experience with them all.

SR-06

Storage and loading system for glass up to 6 metres long, capable of working with any type of coating and thicknesses from 1.8 to 25 mm. The shuttle transports the fully loaded trestles without stopping between two positions, significantly reducing the cycle time.

These systems are particularly notable for their modular construction, so they can grow as the company grows, and for their almost unlimited capacity to adapt to the size and shape of the area, crossing columns and even working between different warehouses.

RUBI 406VA. More automation, more flexibility, more space.

The RUBI 406VA features new, stronger, more reliable and faster loading arms that incorporate a new instant separation system that eliminates the problems associated with the glass sheet separation process.

With this new design, speed and loading time are significantly improved, reducing loading time to a minimum without compromising safety in any way.

The cutting bridge has been specially designed by the TUROMAS engineering team and is made of extruded aluminium, a lightweight material that allows for greater speed and acceleration.

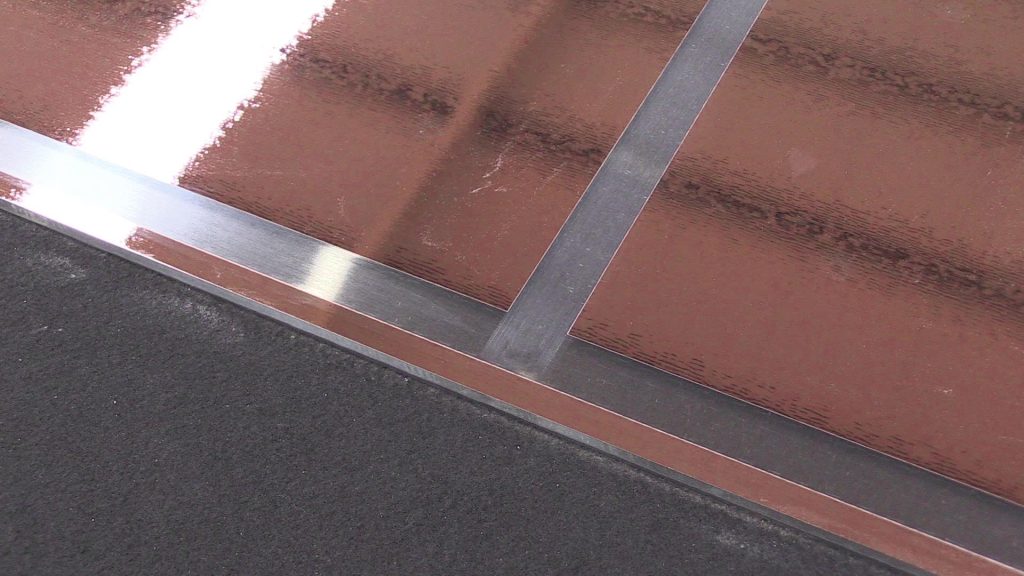

ACR- Advanced Coating Removal for EasyPro glass

The ACR (Advanced Coating Removal) was also on show: a new generation stripping system capable of meeting the needs of today’s market, with maximum quality in a wide range of coatings.

It incorporates patented innovations that improve the glass stripping process, such as the Advanced Cooling System and the two-stage stripping system that prevents the edges of the protective layer from peeling off.

In addition, the equipment includes a high flow 3-phase vacuum for the collection of waste, removing it entirely from the surface.

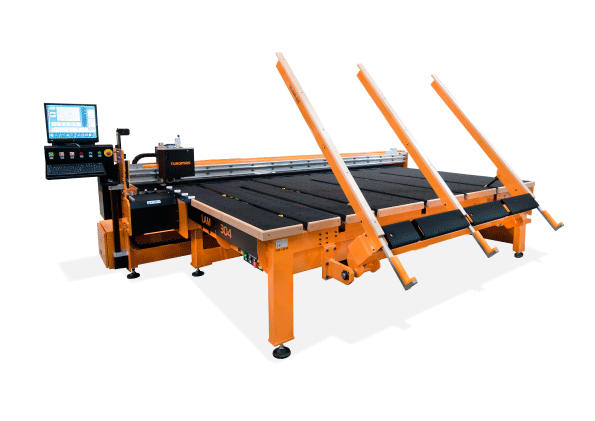

LAM 304 Laminated glass cutting table

In combination with the RUBI 406VA, a cutting table for laminated glass, model LAM 304, was exhibited, forming a mixed line capable of processing both types of glass.

The LAM 304 is a laminated glass cutting solution for companies looking for a versatile machine that provides high quality and performance. Its compact design means the line can cut glass of dimensions 3700 mm and thicknesses up to 10+10 mm.

TUROMAS Software

TUROMAS presented a suite of programs based on Industry 4.0. These applications understand and analyse the operation of equipment based on the data provided by the machines themselves.

- StockGlass, monitors and controls the stock of multiple automated warehouses in real time.

- StoreGlass, manages the stock of material in a non-automated warehouse.

- TuromasLink, integrates TUROMAS’ smart warehouse data with the main ERP solutions on the market.

- LinkGlass fully automates the production sequence, preventing operator intervention in the work order selection and loading sequence processes.

- Cutting TV, an application that allows the automatic display of optimisations. At a glance, the operator has all the information needed for the cutting process.

- TuromasSplitter optimises the laminate cutting time by balancing the work between two cutting bridges.

- SmartGlass lets you view statistics on productivity, availability, efficiency, effectiveness, working hours, processes, materials and produce reports.

Thanks to all the TUROMAS team who made our presence at the fair possible and to all those who came to visit us, enjoyed our customised demonstrations and met our team at our stand.

See you in Düsseldorf for Glasstec 2024.

SHARE

RELATED POSTS

You may also be interested in

The machinery on display in the TUROMAS space will consist of:

SR-06, Rack Shuttle storage system for jumbo glass.

RUBI 406VA: More automation, more flexibility, more space.

ACR- Advanced Coating Removal for EasyPro Glass

LAM 304 Laminated Glass Cutting Table

TUROMAS Software