SR

- Extremely robust structural design

- Outstanding performance and reliability

- Finest quality components

- Industry 4.0 ready

- Remote assistance

- Tailor-made solutions to fit your needs

STANDARD FEATURES

Continuous Traction System

The intelligent SR storage systems have been equipped with a powerful and innovative traction system that provides agile, smooth and continuous movement of the racks to and from the shuttle. Thanks to this system, a fully loaded rack can be moved without stops between two different positions, significantly reducing cycle time.

In addition, the continuous traction system design has been conceived to have a precise rack positioning and movement control at each step of the cycle, thereby minimizing the possibility of machine positioning errors and significantly increasing safety, reliability and life of the equipment.

Flexibility

There is no such thing as an ideal plant. Each one is different and all of them have elements that hinder or block the installation of the machines or their operation, limiting the effective working area to the space between columns of the same hall and always subordinated to the availability of a bridge crane over the entire storage area for glass reloading.

The SR system was born to break with limitations, since it can work between different halls by skipping columns and eliminates the need for a bridge crane covering the entire storage area. Glass is reloaded in the storage area on a specific rack that will be moved within the warehouse by the machine itself.

Gradual expansion

Companies change over time, grow and evolve. The SRs have been modularly designed so that the machine can continue expanding as the company’s needs do, gradually increasing the number of racks and storage area.

Absolute Performance

The set of technologies used in the development of the SR system in combination with the smart mechanical solutions and the high structural robustness have made it possible to create the fastest glass sheet storage in the market without neglecting such important aspects as safety and long-term reliability.

The result is an equipment that provides a performance up to 300% higher, which translates into a machine capable of meeting the needs of the most demanding processor and, at the same time, adapt virtually to any space and type of glass.

Advanced anti-tip system

Safety and performance are perfectly compatible thanks to the Advanced Anti-tipper System, a system with one or more articulated arms whose main function is to ensure that glass will always move safely within the storage area without compromising machine cycle times.

The design of the arm has been optimized to allow the glass to be recharged on the shuttle when required, thereby providing flexibility and versatility.

Structural design

The machines have been designed to optimise storage space, however, with the constant aim of obtaining a higher level of robustness to ensure reliability and smoothness of operation over the years, minimising the vibrations produced during movement to preserve the quality of the glass.

Safety systems

Safety in automatic storage and loading systems is based on ensuring the absence of any individual within the range of action of the machines during operation. To guarantee this premise, a perimetral fence equipped with safety locks isolates the machine’s area of action. In the event that an operator accesses the enclosure while the machine is in operation, the security locks at the entrances detect the action and carry out an immediate and controlled stop. As soon as the enclosure is safe again, the operator can reset the machine to continue with the sequence from the point where it was interrupted.

Electrical system

The electrical system is made up of state-of-the-art devices, exclusively implementing leading-edge digital technology in order to offer maximum speed, precision, quality and reliability. The wiring systems, as well as the electrical cabinets, are designed and tested following the most demanding methodology to provide our customers with the most suitable machines for the toughest working conditions in their daily routine. All machine systems are optimized to work together, without any interference, with a common goal: production.

100% Made in Europe

TUROMAS uses only the best reference European components to guarantee the highest quality, reliability and performance in our machines under any circumstances.

All our machines are completely designed, manufactured and assembled at our facilities in Rubielos de Mora, Spain. This way, we can fully control each of the stages and production processes to ensure the high level of quality that characterizes the brand TUROMAS.

Software

The storage systems, whose control system has been developed under a state-of-the-art programming language, can be linked to and communicated with all major commercial optimizers. The HMI has been created with a technology independent from the operating system, which guarantees implementation under any system on the market..

LR automatic loader

The most versatile solution for transferring glass from the rack to the cutting table is undoubtedly an LR automatic loader. This equipment is equipped with telescopic arms to adapt to different glass sizes and can be either fixed or mobile depending on the feeding needs of the cutting tables.

The LR automatic loader can also be configured with loading arms on one side only or on both sides (bilateral) in order to adapt perfectly to the characteristics of the glass warehouse.

Available for standard size sheets (LR03), Jumbo sheets (LR06) and 7 metre sheets (LR07). The latter version can additionally load a 6 metre sheet, a 3 metre sheet or two 3 metre sheets simultaneously.

VA Cutting Tables

VA cutting tables with TUROMAS loading system are an extremely compact and high-performance automatic glass loading solution. The arms with suction cups that perform the loading function are embedded into the structure of the table, therefore removing the need for an external loader or transfer table. This space optimization makes it possible to allocate the unused area to expand the storage capacity of the SR system.

MODELS

- Simultaneous warehouse reload and loader operation

- Additional control desks

- Shuttles in one or several aisles

- One or Two shuttles in the same aisle

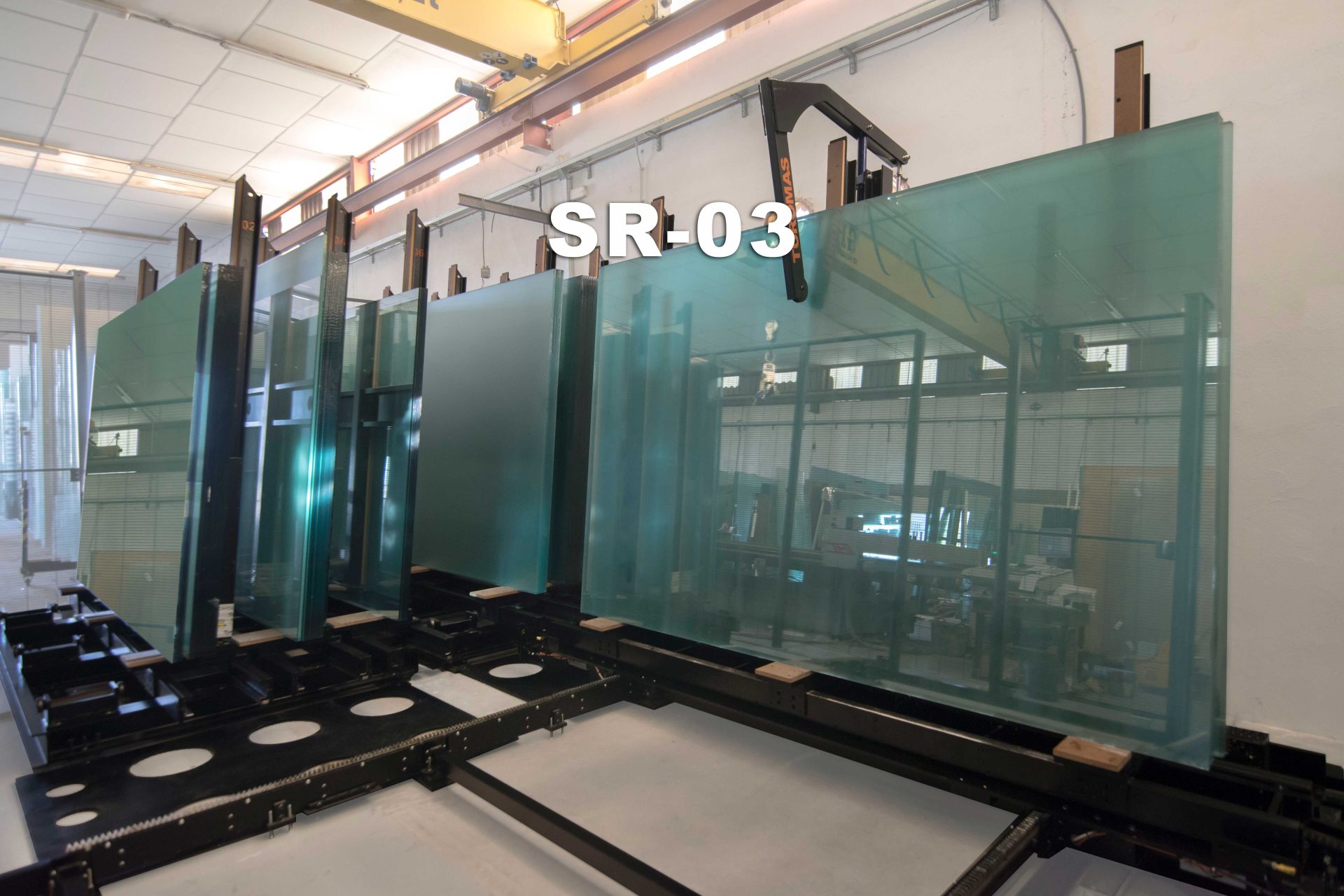

- SR-03

- Minimum cycle time: 60s

- Glass thickness: 1.8 - 25 mm (0.07 - 1")

- Rack loading capacity:

- 5 Tn (11000 Ib)

- 6 Tn (13200 Ib)

- 7 Tn (15400 Ib)

- 8 Tn (17600 Ib)

- Maximum glass size: 3700 x 2550 mm (146“ x 101“)

- Minimum glass size: 1600 x 1600 mm (63” x 63”)

LAYOUT EXAMPLES

- SR-07

- Minimum cycle time: 60s

- Glass thickness: 1.8 - 25 mm (0.07 - 1")

- Rack loading capacity:

- 10 Tn (22000 Ib)

- 12 Tn (26500 Ib)

- 14 Tn (30900 Ib)

- 16 Tn (35300 Ib)

- Maximum glass size: 7000 x 3300 mm (276“ x 130“)

- Minimum glass size: 1800 x 1800 mm (70” x 70”)

LAYOUT EXAMPLES

VIDEOS